Assets are some of the most valuable things that businesses will ever own. If an asset breaks down unexpectedly, operations will be interrupted which may cost companies thousands, or even millions of dollars. To prevent this from happening, businesses need to have full information of an asset, understand how a life cycle of an asset works, and effectively manage each stage of the life cycle.

Key Takeaways

-

- What is Life Cycle Asset Management?

- How many stages are there in the LCAM process? What are they?

- Benefits of LCAM

What Is An Asset?

An asset refers to a resource with economic value owned by an individual, corporation, or government with the expectation that it will provide a benefit in the future.

Asset Management is an ongoing process to evaluate, understand, and optimize the value of the asset to make effective decisions about the assets. Successfully managing assets allow them to run at peak performance and minimize the total costs of obtaining, maintaining, and operating them.

What Is An Asset Life Cycle?

An asset life cycle begins from the moment an asset is purchased by the company and ends when it is disposed of.

The different assets have different life cycles. Depending on several factors such as the cost to replace, the usage frequency, or the importance of an asset, its life cycle can vary.

What Is Life Cycle Asset Management (LCAM)?

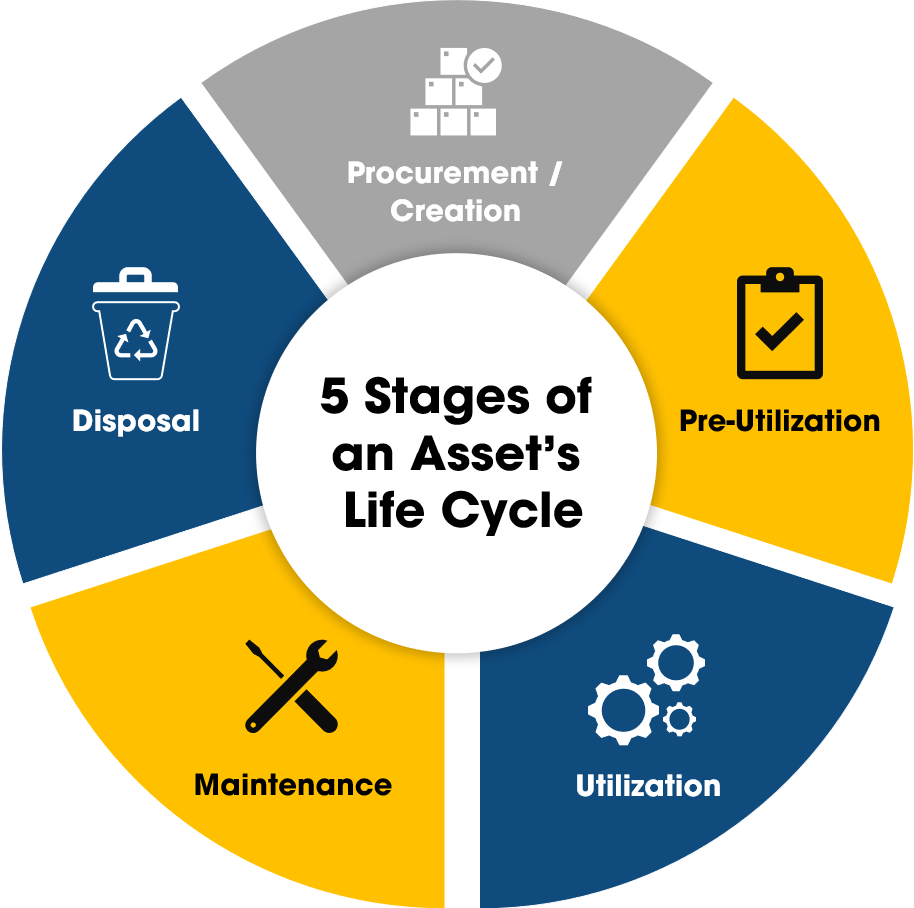

Life Cycle Asset Management (LCAM) is an integrated approach to optimize your assets throughout their life cycle. Whether the asset is big or small, expensive or cheap, it experiences 5 stages in its life cycle.

1. Procurement / Creation

An asset’s life begins when it was purchased, created, or somewhere in between. This is decided depending on the nature of the company. For most companies, procurement is the action that starts the life cycle of an asset. Among available alternatives, the company will make the optimal decision depending on its budget and requirements.

Many mistakes can happen at this stage. If something is miscalculated, it can affect the rest of the stages and can only be fixed at the last stage, which can be more than one year later, and can become much more costly.

2. Pre-Utilization

Before an asset is being used, it will be examined to check for any defects in designs as well as engineering issues or whether it was assembled correctly and safely or not.

3. Utilization

Generally, this is the longest stage of the asset life cycle management process. The main purpose of the utilization stage is to acquire the most output from the asset. Tracking the asset’s performance, transferring to other locations, assigning to other people, purchasing a new license, fixing, auditing are all parts of the utilization stage.

4. maintenance

For every asset, continuous operations will reduce its efficiency and productivity over time. Maintenance helps an asset increase their life which allows them to provide maximum value for the company. Depending on the situation and purposes, organizations will develop and implement different maintenance strategies. To be specific, it could be preventive maintenance, predictive maintenance, or time-based maintenance.

Some companies consider maintenance as an activity in the utilization stage. Meanwhile, others prefer this as a separated phase. In practice, these are two different stages. As when an asset is being maintained, it will be out of action for a specific amount of time.

5. Disposal

Disposing of an asset marks the end of its life. Also, the life cycle management process. Before disposal, companies must ensure that it will not do any harm to the environment. The disposal can take many forms such as donating, recycling, and more.

What Are The Benefits of LCAM?

Life Cycle Asset Management allows companies to make effective decisions that benefit the company in both the short and long term. Some of the benefits include:

|

OPTIMIZE |

MINIMIZE |

|

|

Managing an asset’s life cycle enables organizations to measure its performance, usage frequency, and operating expenses throughout its lifetime. Effectively managing an asset can help businesses gain and maintain a competitive edge against their competitors in the market.